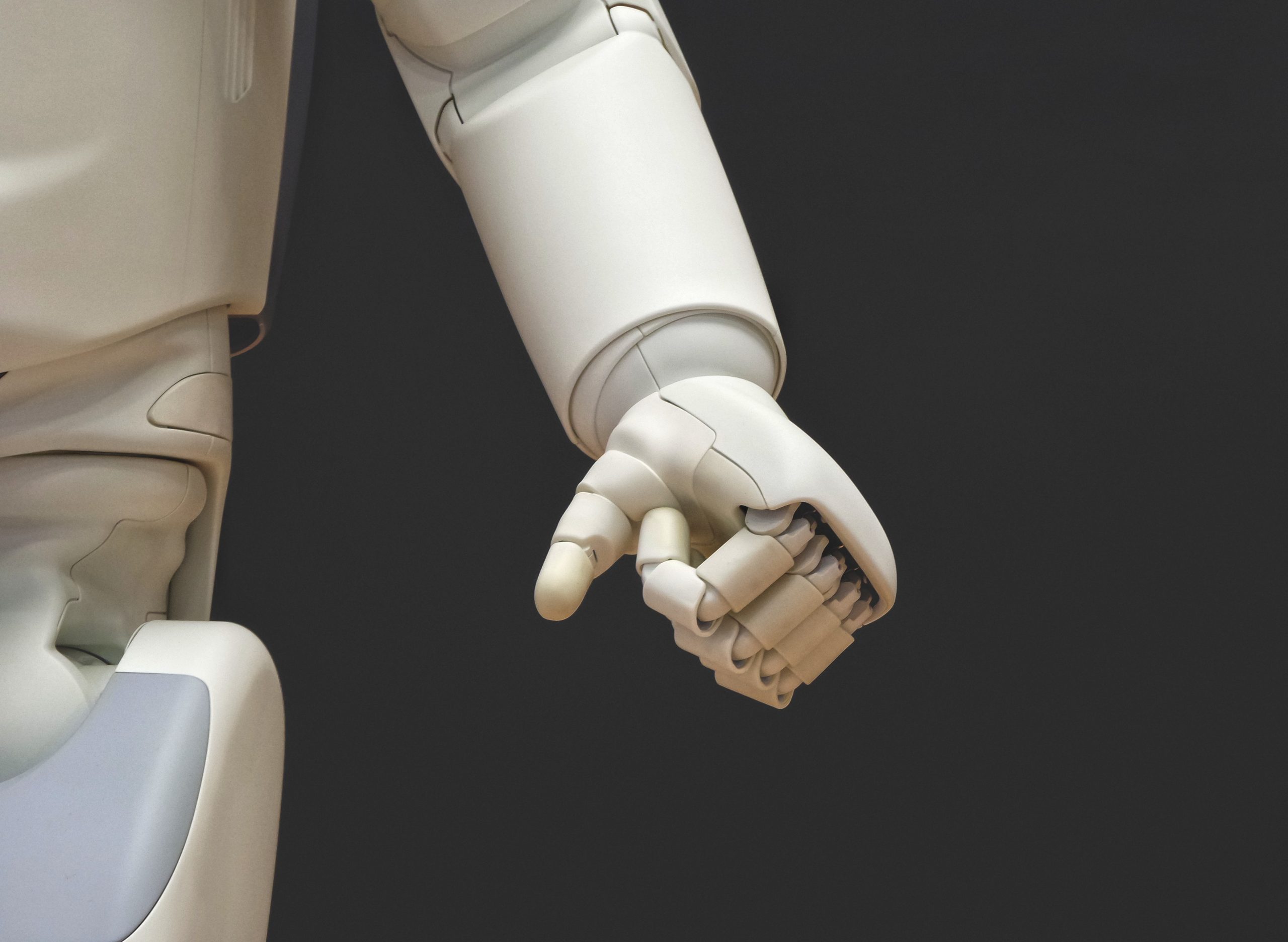

A 3-D-printed bionic hand is in development by a Tunisian startup that hopes to provide an affordable solar powered prosthetic for amputees and disabled people all over Africa.

The artificial hand beats traditional prosthetic devices with its capacity to be customized for youths and children who would otherwise need expensive resized models series as they grow up.

The Cure Bionics Company intends to develop a virtual game-like reality system to educate youngsters on how the artificial hand functions via physical therapy.

The 28-year-old founder Mohamed Dhaouafi, CEO and founder of Cure Bionics, planned his prototype in Souse, where he was an engineering student.

‘’One team member had a cousin who was born without a hand and whose parents couldn’t afford a prosthesis, especially as she was still growing up,’’ he said.

‘’So we decided to design a hand.’’

In 2017 at his family home, Dhaouafi launched his start-up. Many of his classmates were moving abroad to gain international experience and earn more money, but Dhaouafi chose a different path.

‘’It was like positive revenge,” he told AFP. ”I wanted to prove I could do it. I also want to leave a legacy to change people’s lives.”

Dhaouafi pointed at Tunisian hurdles that made it near impossible to buy parts from online large sales sites. There wasn’t enough funding and, he said, ‘’We lack visionaries within the state.’’

Dhaouafi combined the money he raised from sponsored competitions and seed capital an American company awarded him and managed to recruit 4 young engineers.

Now they are perfecting designs, trying out the prosthetic hand, and writing code.

‘Climb like Spiderman’

The device works with sensors attached to the arm which detect muscle movement, with AI-assisted software and interprets this movement then transmits instructions to the digits.

The bionic hand is equipped with a wrist that can turn sideways, fingers that respond to electronic impulses and bend at the joints, and a mechanical thumb.

Teaching youngsters how to use them, Cure has had to work on a virtual-reality headset, which ”gamifies” the process of physical therapy.

”Currently, for rehabilitation, children are asked to pretend to open a jar, for example, with the hand they no longer have,’’ said Dhaouafi.

‘’It takes time to succeed in activating the muscles this way. It’s not intuitive, and it’s very boring.’’

In Cure’s description, the engineer said: ‘’We get them to climb up buildings like Spiderman, with a game score to motivate them, and the doctor can follow up online from a distance.’’

Meanwhile, 3-D printing makes it easy to personalize prosthesis with a fashion accessory or ”a superhero’s outfit,’’ said Dhaouafi.

Cure hopes to take the bionic hand to the market within months within Tunisia and the rest of Africa, where over 75% of people who need them cannot access them, according to the World Health Organization.

‘’The aim is to be accessible financially but also geographically,’’ said Dhaouafi.

The anticipated substantial price of between $2,000 to $3,000 is just a fraction of bionic prostheses cost currently imported from Europe.

‘Leapfrog Technology’

Cure aims at manufacturing the closest possible to end-users, where local technicians measure the patient’s and then print custom made-to-order devices.

‘’An imported prosthesis today means weeks or even months of waiting when you buy it, and again with each repair,’’ the inventor said.

The bionic hand is built from detachable parts that are easy to replace when damaged.

It could also be run with solar energy through a photovoltaic suitable for regions with unreliable electricity.

The rudimentary prosthesis 3-D printing started around a decade ago, and it’s becoming standard.

The solution is not magic since specialized medical skills are very vital, observed Jerry Evans, the Nia Technologies head, a non-profit organization from Canada that helps hospitals in Africa manufacture 3-D-printed lower extremities.

3-D printing is still in its early stages,” he said, ”but it is a major game-changer in the field of prosthetics and orthotics.”

‘’Developing countries will probably leapfrog to these technologies because the cost is much lower.’’

Home4 years ago

Home4 years ago

Medical4 years ago

Medical4 years ago

Gadgets4 years ago

Gadgets4 years ago

Environment4 years ago

Environment4 years ago

Medical4 years ago

Medical4 years ago

Energy4 years ago

Energy4 years ago