In a surprising twist of technological fashion, the world of consumer electronics is experiencing a renaissance of transparent design. This trend, reminiscent of the late 1990s and early 2000s, is making a comeback with a modern flair, captivating both nostalgic enthusiasts and new-age tech aficionados alike. From smartphones to earbuds, the allure of see-through gadgets is once again capturing the imagination of consumers and manufacturers.

The resurgence of transparent tech was notably kickstarted by Nothing, a London-based company founded by Carl Pei, co-founder of OnePlus. Nothing’s debut product, the Ear 1 wireless earbuds, featured a distinctive transparent design that quickly caught the attention of the tech world. This bold move set the stage for a broader revival of transparent aesthetics in consumer electronics.

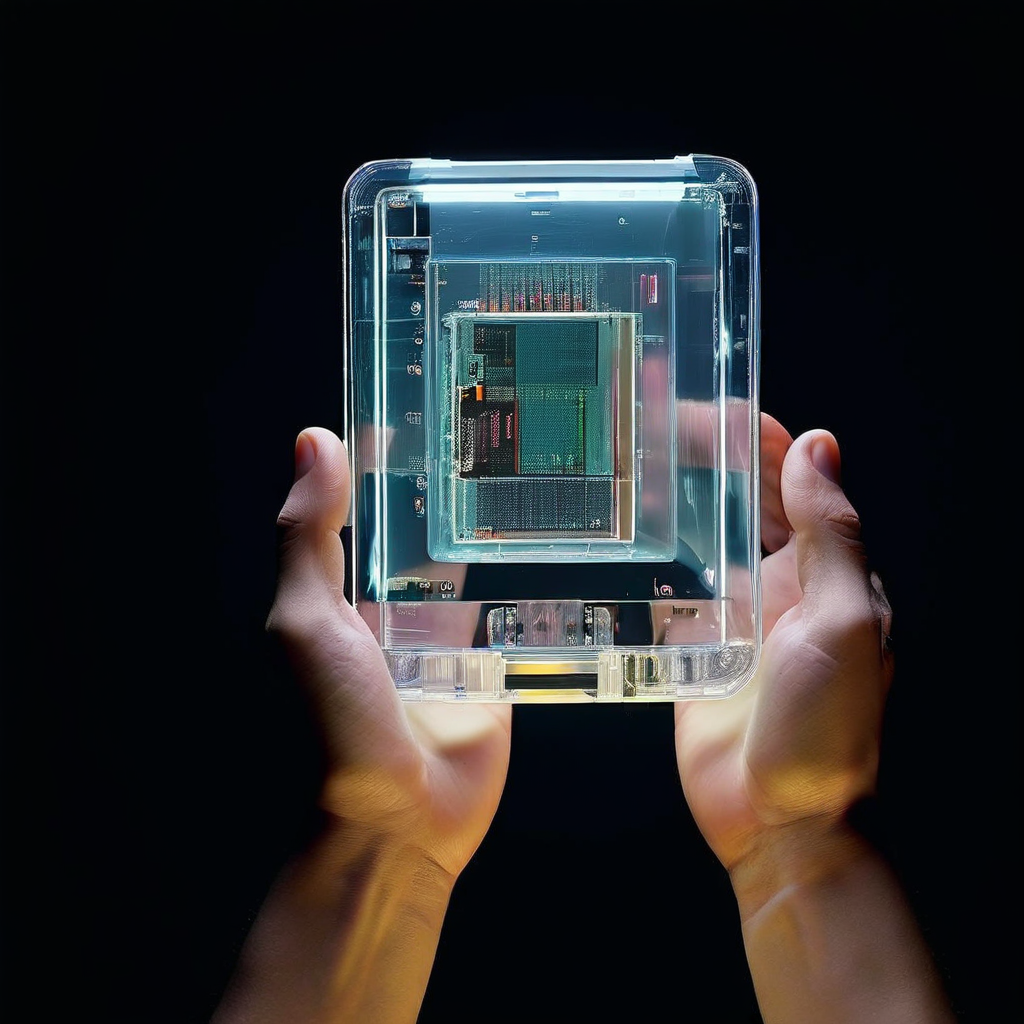

The appeal of transparent design lies in its ability to showcase the intricate inner workings of our devices. As noted by the Consumer Technology Association, this trend aligns with a growing consumer interest in understanding the technology they use daily. Transparent gadgets satisfy this curiosity by offering a literal window into the complex circuitry and components that power our digital lives.

One of the most significant entries in this transparent tech renaissance is Nothing’s Phone 2, which builds upon the success of its predecessor. The Phone 2 features a transparent back panel that reveals a unique arrangement of LED lights, dubbed the “Glyph Interface.” This innovative design element not only serves aesthetic purposes but also functions as a notification system and charging indicator, demonstrating how transparency can be both visually appealing and functional.

The trend isn’t limited to smartphones and earbuds. Gaming peripherals are also embracing the transparent aesthetic. Logitech has introduced a line of transparent gaming accessories, including keyboards and mice, under its G brand. These products feature a frosted transparent design that allows RGB lighting to shine through, creating a mesmerizing effect that appeals to gamers and tech enthusiasts alike.

Even established brands are jumping on the transparent bandwagon. Beats, the Apple-owned audio company, has released a limited edition of its Studio Buds featuring a transparent design. This move signals that major players in the tech industry recognize the growing demand for visually distinctive products that stand out in a crowded market.

The resurgence of transparent tech isn’t just about aesthetics; it also reflects a broader shift in consumer values. According to a report by the Environmental Protection Agency, there’s a growing awareness of electronic waste and its environmental impact. Transparent designs can potentially contribute to this awareness by making the internal components of devices more visible and, by extension, more relatable to consumers. This visibility might encourage users to consider the longevity and repairability of their devices, aligning with the principles of the Right to Repair movement.

However, the transparent tech trend faces challenges. Manufacturers must balance the desire for transparency with the need for durability and functionality. As pointed out by the Institute of Electrical and Electronics Engineers (IEEE), transparent materials often have different physical properties compared to traditional opaque materials used in electronics. This can affect everything from heat dissipation to signal interference, requiring innovative engineering solutions to maintain performance standards.

Moreover, the trend raises questions about privacy and security. With internal components exposed, there’s a potential risk of revealing sensitive information about a device’s architecture. The National Institute of Standards and Technology (NIST) emphasizes the importance of considering security implications in product design, which becomes particularly relevant when internal components are visible.

Despite these challenges, the transparent tech trend shows no signs of slowing down. Companies are exploring new ways to incorporate transparency into their products. For instance, Xiaomi has showcased a concept phone with a fully transparent display, pushing the boundaries of what’s possible with transparent technology. While such concepts may not be immediately feasible for mass production, they demonstrate the industry’s commitment to innovation in this space.

The revival of transparent tech also intersects with other emerging trends in consumer electronics. As noted by the International Data Corporation (IDC), there’s a growing interest in customizable and modular devices. Transparent designs could potentially facilitate this trend by making it easier for users to understand and interact with the components of their devices.

Furthermore, the transparent tech trend is influencing industries beyond consumer electronics. In the automotive sector, companies like Tesla are exploring transparent solar roofs for electric vehicles, combining aesthetics with functionality. This cross-pollination of ideas suggests that the impact of the transparent tech trend could extend far beyond smartphones and earbuds.

As we look to the future, it’s clear that transparent tech is more than just a passing fad. It represents a convergence of nostalgia, innovation, and changing consumer values. The Consumer Electronics Show (CES), the world’s largest technology trade show, has seen an increase in transparent tech exhibits, indicating strong industry support for this trend.

However, the long-term success of transparent tech will depend on its ability to offer more than just visual appeal. As the MIT Technology Review points out, lasting technological trends are those that provide tangible benefits to users. For transparent tech to truly thrive, it must continue to innovate in ways that enhance functionality, durability, and user experience.

In conclusion, the resurgence of transparent tech marks an exciting chapter in the evolution of consumer electronics. It challenges designers and engineers to rethink the relationship between form and function, pushing the boundaries of what’s possible in product design. As this trend continues to develop, it has the potential to reshape our expectations of how technology should look and feel.

The transparent tech renaissance is more than just a nostalgic callback; it’s a forward-looking movement that combines aesthetic appeal with technological innovation. As consumers, we can look forward to a future where our devices are not just tools, but also works of art that invite us to appreciate the ingenuity behind them. The clear message from the tech industry is that transparency is not just about seeing through our devices, but about seeing into the future of technology itself.

Home4 years ago

Home4 years ago

Medical4 years ago

Medical4 years ago

Gadgets4 years ago

Gadgets4 years ago

Environment4 years ago

Environment4 years ago

Medical4 years ago

Medical4 years ago

Energy4 years ago

Energy4 years ago